In early September, at an industrial facility located about 25 miles southeast of Reykjavik, Iceland, the Swiss company Climeworks will mark the opening of a new project named “Orca.” At least in a conventional sense, Orca doesn’t actually make anything. It is comprised of eight elongated boxes that resemble wood-clad tanks. Each of these boxes — known as “collectors” — is roughly the size of a tractor trailer, and each is festooned with 12 whirring fans that draw a stream of air inside. Within the collectors, a chemical agent known as a sorbent will capture CO2 contained in the air wafting through. Periodically, the surface of the sorbent will fill up. And at that point the CO2 trapped within it will need to be released. At Orca, this task is accomplished with a blast of heat, which is sourced from a nearby hydrothermal vent. The extracted CO2 will then be piped from the collector boxes to a nearby processing facility, where it will be mixed with water and diverted to a deep underground well.

And there it will rest. Underground. Forever, presumably. The carbon dioxide captured from the Icelandic air will react with basalt rocks and begin a process of mineralization that takes several years, but it will never function as a heat-trapping atmospheric gas again.

Climeworks maintains that Orca, once it’s running around the clock, will remove up to 4,000 metric tons of CO2 from the atmosphere each year. And there isn’t much reason to doubt the facility can achieve this feat. For one thing, the technology for the plant, known as direct air capture, or DAC, is a variation on ideas that have been utilized over the course of half a century in submarines and spacecraft: Employ chemical agents to “scrub” the excess CO2 out of the air; dispose of it; then repeat. More to the point, perhaps, is the fact that Climeworks has already built smaller, less sophisticated plants in mainland Europe, which have in turn pulled hundreds of tons of CO2 per year from ambient air.

We are out of academic research and feasibility and into engineering reality.

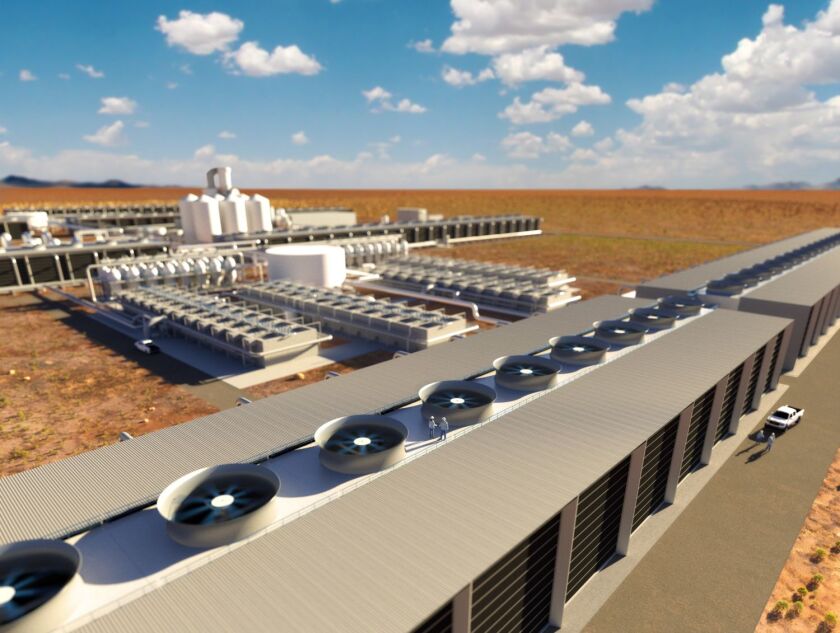

And yet, Climeworks and Orca will likely soon be eclipsed. Plans for even larger DAC plants — one in the U.S. Southwest, slated for completion at the end of 2024; another in Scotland, to be finished about a year after the American project — will be built by a competitor, Carbon Engineering, of British Columbia. Employing a somewhat different technology, Carbon Engineering’s facilities, as initially planned, will be powered by renewable energy and will eventually each remove, on net, about a million metric tons of carbon dioxide a year from the atmosphere.

“In our view, this will decisively answer the question: Is direct air capture feasible at large scale and affordable cost,” Steve Oldham, the CEO of Carbon Engineering, told me recently. “As I see it, we are out of academic research and feasibility and now into engineering reality.”

CLIMEWORKS

Without question, the best way to begin doing so is to drastically transform our electrical, transportation, and industrial systems to emissions-free energy sources and processes. However, we may need to actively compensate for economic sectors — air travel, for instance, or steel production — that prove too hard to rapidly decarbonize. This would mean we would have to actively take CO2 out of the atmosphere at the same time. Our carbon removal efforts could involve natural means, such as sequestering atmospheric CO2 in soil or new forests. But we could also utilize more technological approaches, such as DAC or bioenergy with carbon capture and storage — known by the acronym BECCS—which involves growing plants, burning or fermenting them for energy, and then capturing the CO2 emissions and burying them.

And here the numbers get daunting. Zeke Hausfather, a climate scientist at the nonprofit Berkeley Earth involved in charting possible emission pathways for the IPCC report, told me that in one of the most optimistic scenarios, which limits temperature rises to 1.5 degrees C by 2100, the conditions require massive mitigation efforts as well as about 17 gigatons — that’s billions of tons — of CO2 removal per year by the end of the century. And as much as planting trees might seem an ideal solution to help us reach such a goal, new forests are likely not a sufficient or durable carbon removal solution, especially in the wake of huge wildfires in Siberia and the American West. “Natural ways of removing CO2 are generally less desirable than long-term geologic storage through BECCS or DAC,” Hausfather says, adding that this is because storing carbon above ground in biomass is most likely temporary.

Whether direct air capture “scales up” and makes a significant climate impact depends mainly on its expense.

In several instances over the past few years, in the course of reporting on climate solutions and carbon removal strategies, I’ve been told by venture capitalists — investors I respect for their grasp of technology, and who have a deep understanding of climate change — that direct air capture could turn out to be among the world’s biggest industries by midcentury. I would not be shocked if this turns out to be true. On the other hand, even modest growth of the DAC industry seems entirely conditional. Reducing emissions — a Herculean task for the world’s governments and industries as they begin to phase out fossil fuels — remains the primary challenge. And beyond that, whether DAC “scales up” and makes a significant climate impact depends mainly on its expense. Or to put it another way: How much will it ultimately cost to separate a metric of ton of CO2 from the air and put it into the ground, or into a long-lasting product like concrete or carbon fiber? It seems a matter of consensus that if it can get nearer to $100 per ton, direct air capture might become an essential and useful technology.

But we’re still not sure. A few years ago, Climeworks executives told me their cost of direct air capture was somewhere between $500 and $600 per ton. The company is not publicly estimating — and indeed may not yet know — how much the Orca plant will improve on that measurement. Still, there are physical and thermodynamic limits, according to the DOE’s Wilcox, that can help serve as a lower bound. Wilcox surmises that scientific constraints may make it difficult for Climeworks or Carbon Engineering plants to get much below $100 per ton to remove carbon from the air. And this may remain the case no matter how hard engineers work in the future to bring down expenses through cheaper materials and assembly-line industrialization. A recent analysis of the industry, authored by scientists at Carbon Engineering, predicts a similar outcome: An eventual cost range for DAC of between $94 and $232 per ton. That could be decades away — or it may never come to pass.

CARBON ENGINEERING LTD.

It’s probably best to interpret the opening of the new plants as the start of a complex, multi-decade, global deployment process that follows years of research and development. “We’re confident our costs will continue to fall,” Oldham, the Carbon Engineering CEO said. “But only if we deploy. If you never deploy, your costs never go down.”

Oldham’s view, moreover, is that the world might, through epic efforts at mitigation, be able to eliminate 70 to 80 percent of emissions by 2050. “But that would leave about 20 to 30 percent of the carbon footprint we’re going to have to remove,” he says — probably the equivalent of about 10 to 12 billion tons per year of CO2. As a thought experiment, that would require 10,000 Carbon Engineering plants like the ones the company is now planning. “I think if the world sets its mind to it, we can produce many of these plants,” he said. “And we’ve done this in the past. Look at the way we scrambled for Covid vaccines. Or look at the way we scrambled for wars and got into the mass production of planes.”

A key question is whether direct air capture eventually mimics the astonishing cost declines of solar PV panels.

At the same time, investment dollars are beginning to flow into “next generation” DAC ideas. The U.S. Department of Energy recently invested more than $12 million in a slew of early-stage approaches and component technologies. A number of venture firms, notably Breakthrough Energy and LowerCarbon Capital, have placed tens of millions more into startups. One new firm, San Francisco-based Noya, utilizes existing power plant cooling towers to create a “distributed” system of direct air capture stations that the company hopes will prove cheaper than building DAC plants from scratch; another, a Detroit-based startup known as Remora, fits carbon-capturing sorbent technology on trucking rigs to vacuum up CO2 on long hauls. As a sweetener, a new $100 million X-prize, sponsored by Elon Musk, involves a four-year global competition that will reward the most promising young carbon removal firms for ideas that can be scaled up to gigatons per year.

So within the industry, there is plenty of money and plenty of enthusiasm. What is in short abundance, in light of the hottest month on record and near-term projections for future global temperatures, is plenty of time.

At this stage in DAC’s evolution, it’s worth recalling that it can be notoriously hard to predict how long it takes for technologies to mature. In the mid-1950s, just after the first practical photovoltaic solar cell was invented at Bell Labs in New Jersey, one of its inventors, Daryl Chapin, calculated it would cost around $1.5 million to deploy the devices as an electricity source on a typical American house. Nowadays, you can outfit a home with solar panels for around $20,000, according to the Solar Energy Industries Association — and that investment pays off over time through the benefit of cheaper electric bills. In some locations, solar PV is now the cheapest source of energy on the planet.

CARBON ENGINEERING LTD.

“My opinion is that if it behaves like many other mass manufactured technologies, it is not unreasonable to assume that by growing roughly 300-fold, we should be skirting $100 per ton for carbon removal,” Lackner says. “Beyond that, my crystal ball is a little cloudy. But if this keeps growing a thousand-fold, we should be at $50, or maybe $70 or $80 per ton.”

Lackner believes that DAC may actually be at a better stage than solar photovoltaics were during, say, the 1970s, when prices were prohibitively expensive. For widespread adoption, solar technology needed to reduce costs by about 100 times, he says. DAC needs only to reduce costs by 10 times to make it desirable. He acknowledges there is no guarantee that DAC will succeed in the same way as it scales up. And he warns that even if direct air capture costs drop dramatically, the world will still need a regulatory framework for its application, so as to make a significant impact on the climate. As crucial as it may be to improve the technology, it will be equally important to compel industries and governments “to treat CO2 as a waste product,” he says, and therefore pay to clean it up.

In light of this, the next few years should be telling. We may soon know whether DAC is a go—or whether the technology, often viewed by its critics as quixotic, will hit a wall of inefficiency. If it’s the former, we will have a useful tool in the climate toolbox. But if it’s the latter, it will almost certainly make the goal of achieving a livable world more complicated. The work ahead of us, already monumental in its political, technological, and economic challenges, would become even more difficult.